Advanced Engineering

We support our customers from the very first steps of the projects

until the end, from the study and characterization of each single test,

to the numeric experimental correlation.

Advanced

Engineering

DESIGNED TO

Resist

DESIGNED TO

Innovate

DESIGNED TO

Overcome

DESIGNED TO

Run

DESIGNED TO

Succeed

DESIGNED TO

Perform

DESIGNED TO

Resist

DESIGNED TO

Overcome

DESIGNED TO

Succeed

DESIGNED TO

Innovate

DESIGNED TO

Run

DESIGNED TO

Perform

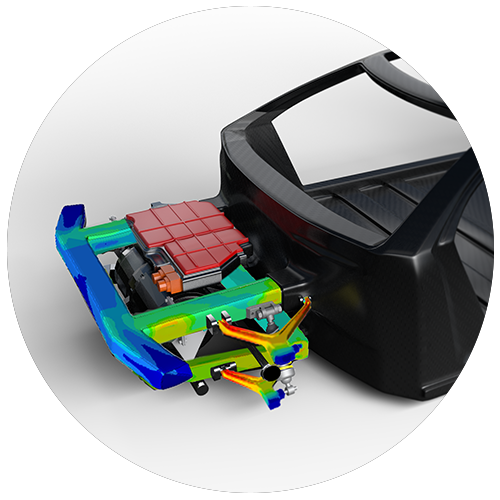

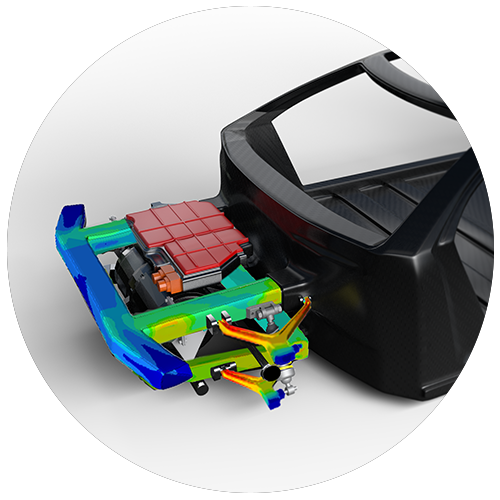

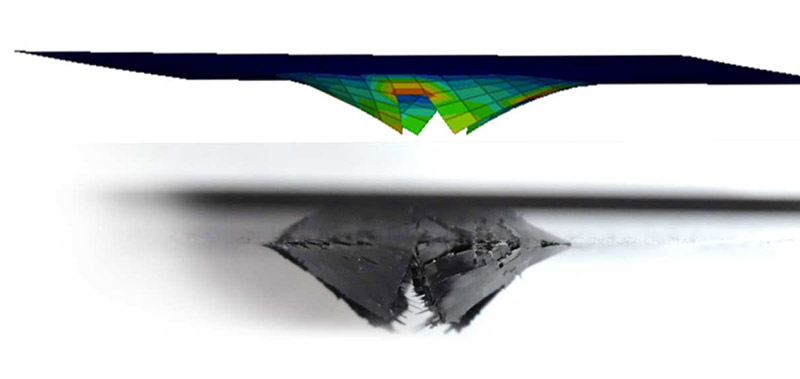

DESIGNED TO RESIST

Structural FEM Analysis & Experimental-Numerical Correlation

In our company, we design, analyze and test composite, metallic and hybrid material components with the help of cutting edge computing technology, to ensure the highest level of quality and reliability throughout the project, optimizing costs and development time.

Our know-how, acquired through hands-on experience, various industrial projects for customers, and R&D projects, allow us to take care of each aspect of the project, applying all the engineering disciplines, with an holistic approach.

This mindset allows us to integrate various skills that usually are found in various companies and hence, we can provide a wide offer. Thanks to the numerous combined expertises, we support our customers from the very first steps of the projects until the end, from the study and characterization of each single test, to the numeric experimental correlation.

DESIGNED TO RESIST

Structural FEM Analysis & Experimental-Numerical Correlation

In our company, we design, analyze and test composite, metallic and hybrid material components with the help of cutting edge computing technology, to ensure the highest level of quality and reliability throughout the project, optimizing costs and development time.

Our know-how, acquired through hands-on experience, various industrial projects for customers, and R&D projects, allow us to take care of each aspect of the project, applying all the engineering disciplines, with an holistic approach.

This mindset allows us to integrate various skills that usually are found in various companies and hence, we can provide a wide offer. Thanks to the numerous combined expertises, we support our customers from the very first steps of the projects until the end, from the study and characterization of each single test, to the numeric experimental correlation.

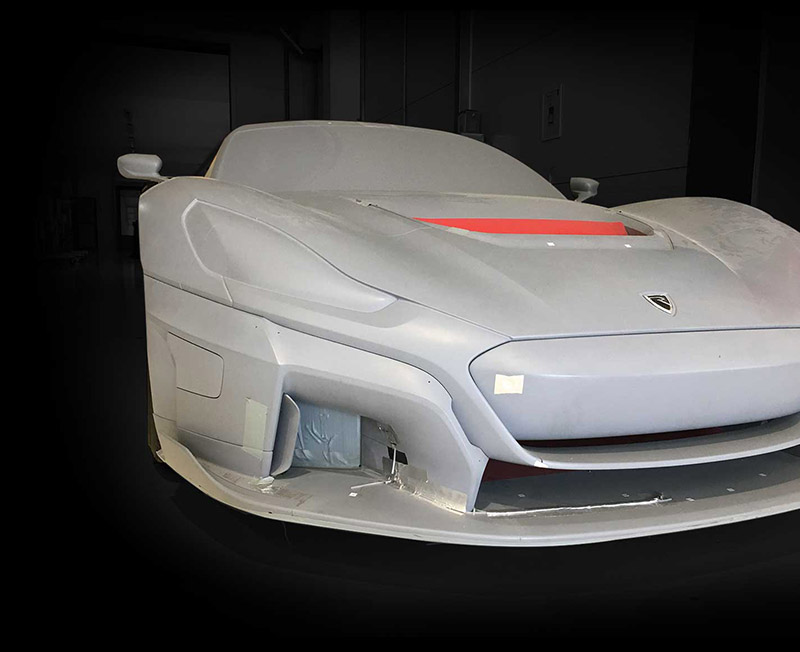

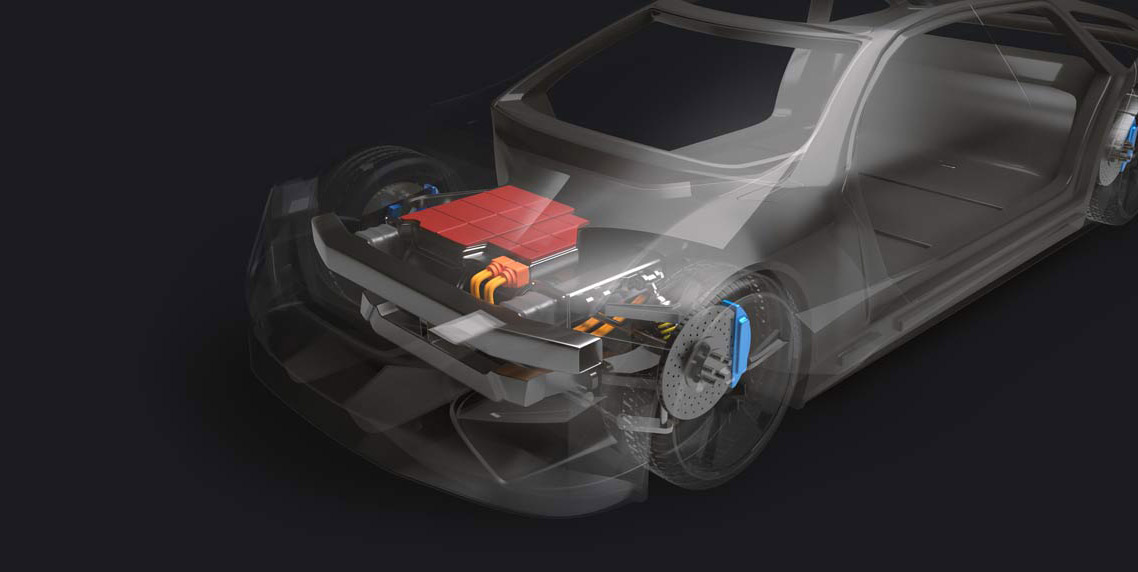

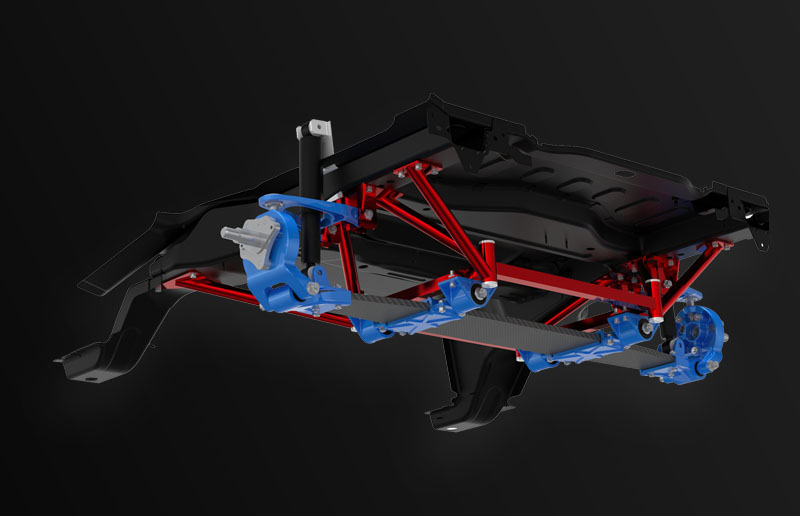

DESIGNED TO INNOVATE

Mechanical design of systems and assemblies, test equipment design, vehicle design, systems assembling, components prototyping and new product concepts

BeonD develops projects for the realization of high-tech innovative prototypes and demonstrators in various sectors: automotive, industrial, aerospace, marine and railway.

Our experts team is able to take in charge the entire development process of a new product, -from the concept through the designing, to the manufacturing- with the support of advanced modelling techniques, design systems and CAD software, and the knowledge of the most advanced material and their manufacturing technologies.

A solid network of highly qualified suppliers and workshops, enables us to create, in addition to the concepts, also advanced prototypes, provided with all the functions our customers have required.

DESIGNED TO INNOVATE

Mechanical design of systems and assemblies, test equipment design, vehicle design, systems assembling, components prototyping and new product concepts

BeonD develops projects for the realization of high-tech innovative prototypes and demonstrators in various sectors: automotive, industrial, aerospace, marine and railway.

Our experts team is able to take in charge the entire development process of a new product, -from the concept through the designing, to the manufacturing- with the support of advanced modelling techniques, design systems and CAD software, and the knowledge of the most advanced material and their manufacturing technologies.

A solid network of highly qualified suppliers and workshops, enables us to create, in addition to the concepts, also advanced prototypes, provided with all the functions our customers have required.

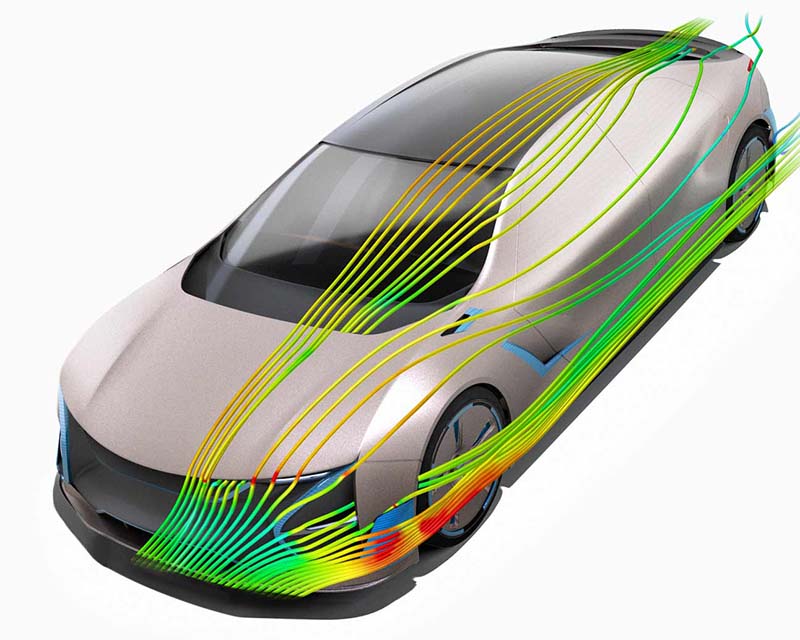

DESIGNED TO OVERCOME

CFD Analysis, Aero-Design, Thermal 1D and 3D Analysis, Thermal Management System Design and Analysis

The approach we apply in BeonD stands out for combining solutions obtained using lateral thinking. We think out-of-the-box.

Our experts Team take in hand the 1D thermal models designing, 3D thermal fluid dynamics, aerodynamic optimization with all the attention of passionate people who love their job.

The team is specialized on important aerodynamic optimization projects of electric hyper-cars, which broadened our know-how especially what concerns E-mobility new technologies.

DESIGNED TO OVERCOME

CFD Analysis, Aero-Design, Thermal 1D and 3D Analysis, Thermal Management System Design and Analysis

The approach we apply in BeonD stands out for combining solutions obtained using lateral thinking. We think out-of-the-box.

Our experts Team take in hand the 1D thermal models designing, 3D thermal fluid dynamics, aerodynamic optimization with all the attention of passionate people who love their job.

The team is specialized on important aerodynamic optimization projects of electric hyper-cars, which broadened our know-how especially what concerns E-mobility new technologies.

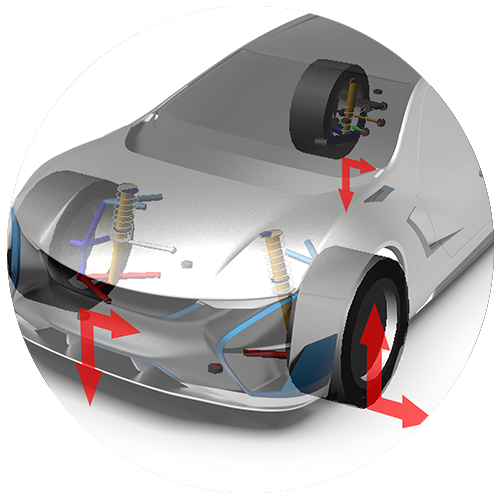

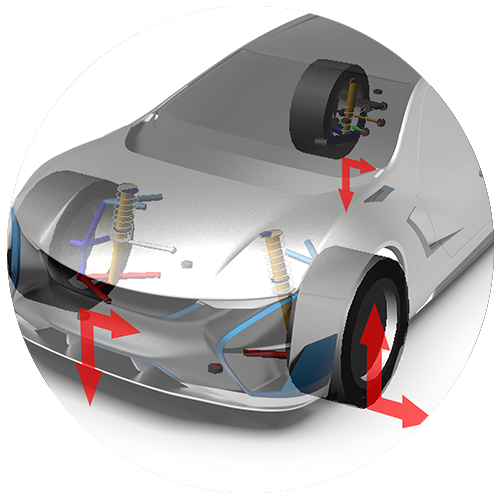

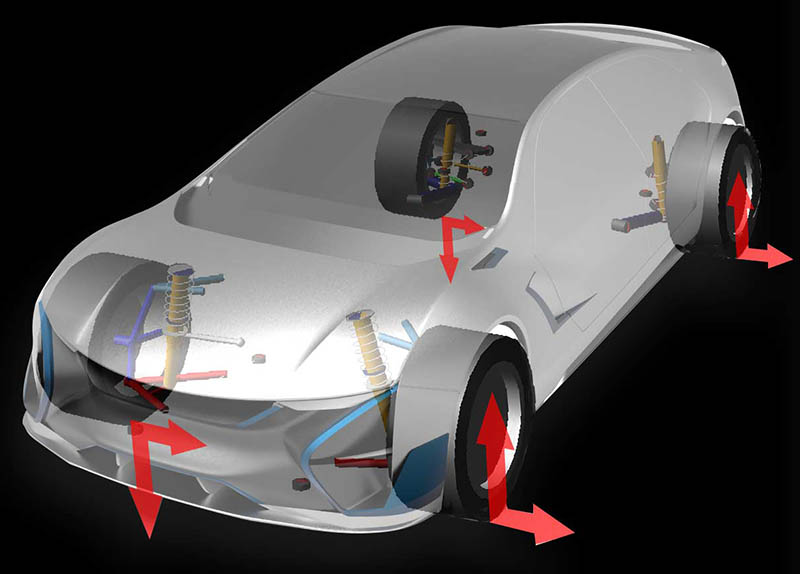

DESIGNED TO RUN

Vehicle Dynamics Modeling, Multibody Analysis, Noise Vibration and Harshness Analysis

Dynamics enable us to predict and design complex systems behaviors and performances such as vehicle suspension systems, mechanical assemblies and industrial machines.

BeonD’s dynamics models, instruments and methods permit to accurately simulate the subsystems and the whole assembly (or full vehicle) performance using multibody software and solvers. Our customers’ design team can use all input data needed to reach high performance and safety standards.

DESIGNED TO RUN

Vehicle Dynamics Modeling, Multibody Analysis, Noise Vibration and Harshness Analysis

Dynamics enable us to predict and design complex systems behaviors and performances such as vehicle suspension systems, mechanical assemblies and industrial machines.

BeonD’s dynamics models, instruments and methods permit to accurately simulate the subsystems and the whole assembly (or full vehicle) performance using multibody software and solvers. Our customers’ design team can use all input data needed to reach high performance and safety standards.

DESIGNED TO SUCCEED

Experimental Tests & Material Characterization

BeonD stands out in the engineering market thanks to its laboratory for the characterization of unconventional materials (such as composite materials) and their systems where these materials are applied. In this laboratory a new material can be totally qualified and a material card for virtual analysis can be created thanks to a vertical process.

The presence of an internal laboratory, equipped with the most advanced and performing acquisition systems and data-logging, allows us to innovate, experiment, define standard tests (when the current legal framework don’t provide information or detailed guidelines) or customized ( according to the customer requests and special needs).

DESIGNED TO SUCCEED

Experimental Tests & Material Characterization

BeonD stands out in the engineering market thanks to its laboratory for the characterization of unconventional materials (such as composite materials) and their systems where these materials are applied. In this laboratory a new material can be totally qualified and a material card for virtual analysis can be created thanks to a vertical process.

The presence of an internal laboratory, equipped with the most advanced and performing acquisition systems and data-logging, allows us to innovate, experiment, define standard tests (when the current legal framework don’t provide information or detailed guidelines) or customized ( according to the customer requests and special needs).

DESIGNED TO PERFORM

Durability, Passive Safety, NVH, Thermal System, HVAC, Aerodynamics, Chassis System, BMS and Batteries

Target, definition, performance pursuit and technical goals, cost analysis, optimization loop. In a few words: Performance engineering.

For each project we create a unique synergy between the thirty year experience of our senior consultants and senior advisors and the most advanced technologies and expertises of our Core Team. Through this synergy, we are able to follow the entire process, from the concept and goals and performance setting to their achievement, through a continuous analysis of the complex system, the vehicle or product even after the SOP (start of production).

DESIGNED TO PERFORM

Durability, Passive Safety, NVH, Thermal System, HVAC, Aerodynamics, Chassis System, BMS and Batteries

Target, definition, performance pursuit and technical goals, cost analysis, optimization loop. In a few words: Performance engineering.

For each project we create a unique synergy between the thirty year experience of our senior consultants and senior advisors and the most advanced technologies and expertises of our Core Team. Through this synergy, we are able to follow the entire process, from the concept and goals and performance setting to their achievement, through a continuous analysis of the complex system, the vehicle or product even after the SOP (start of production).